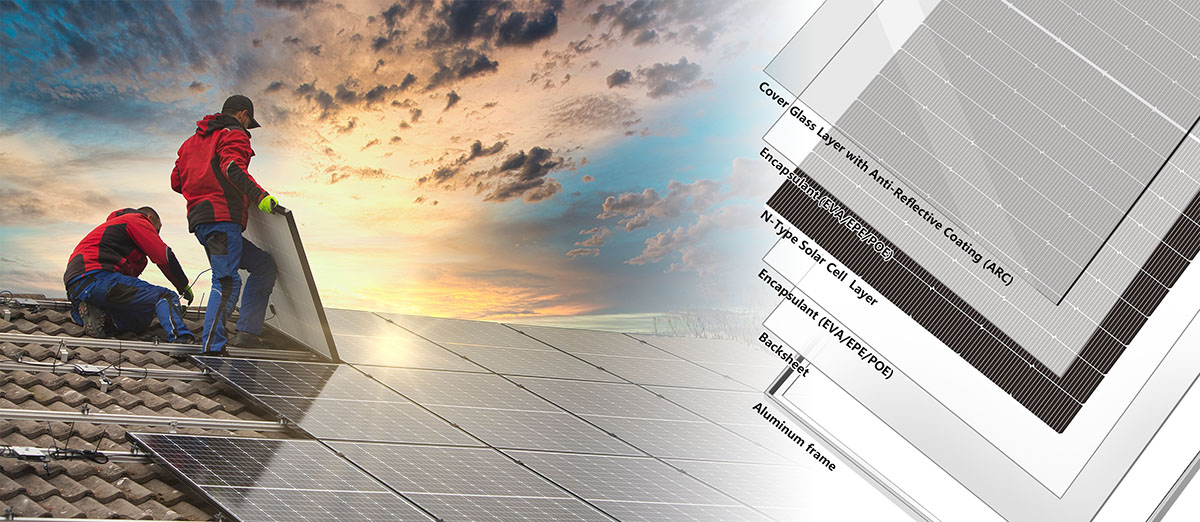

Ukwakheka kwesakhiwo samapaneli elanga

Ngokuthuthuka okusheshayo kwemboni yamandla elanga, imboni yokukhiqiza iphaneli yelanga nayo ithuthuka ngokushesha. Phakathi kwabo, ukukhiqizwa kwamapaneli elanga kuhilela izinto ezihlukahlukene, futhi izinhlobo ezahlukene zamapaneli elanga zingase futhi zakhiwe ngezinto ezihlukahlukene.

1.Akhiwe ngani ama-solar panel?

Amaphaneli elanga ngokuvamile akhiwe ngokuyinhlokoama-silicone wafers, emuvaishidi, ingilazi, i-Eva,futhiamafreyimu e-aluminium:

·Ama-Silicon wafers: izingxenye eziyinhloko zamaphaneli elanga

Njengezingxenye ezibalulekile zamaphaneli elanga, ama-silicon wafers nawo adlala indima ebalulekile kumamojula welanga, futhi kunezinhlobo eziningi ngokuya ngezakhiwo ezahlukahlukene.

Indima yama-silicone wafers

Ukuguqulwa kwe-Photoelectric: Ama-wafer e-silicon angaguqula ukukhanya kwelanga kube amandla kagesi, okuwumsebenzi oyinhloko wamaphaneli elanga.

Izakhiwo ze-Semiconductor: I-Silicon iyimpahla ye-semiconductor engalungisa ukuqhutshwa kwayo nge-doping (okungukuthi, ukwengeza inani elincane lezinye izakhi ku-silicon) ukuze yakhe i-PN junction futhi ibone ukuqoqwa nokudluliswa kwe-photocurrent.

Izinhlobo zama-silicone wafers

I-Monocrystalline silicon wafers: Yenziwe nge-silicon enesakhiwo esisodwa sekristalu, inokusebenza kahle kakhulu nokuzinza, kodwa izindleko ziphezulu.

Amawafa e-Polycrystalline silicon: Yenziwe nge-silicon enezinhlaka eziningi zekristalu, inenani eliphansi, kodwa ukusebenza kahle kwayo nokuzinza kwayo kungaphansi kancane kune-monocrystalline silicon wafers.

Ama-wafers e-silicon ecwebezelayo: sebenzisa impahla ye-silicon encane, alula futhi abiza kancane, kodwa asebenza kahle kancane.

Ilanga lasolwandleihlale ikhethela amakhasimende amawafa e-solar asezingeni eliphezulu kakhulu ukuze aqinisekise ukuthi iseli ngalinye liwuphawu lweBanga A.Ilanga lasolwandleIzidingo zamandla eseli nazo ziphakeme kakhulu kunemikhiqizo efanayo.

·I-Backsheet: Ingxenye eyinhloko yamaphaneli elanga

Ukuvikela: I-backsheet ivikela izingxenye zangaphakathi zamaphaneli elanga (njengama-silicon wafers, amaseli nezintambo) ezicini zemvelo (njengomswakama, uthuli, imisebe ye-ultraviolet, njll.), ukwelula impilo yesevisi yezingxenye.

Ukufakwa kukagesi: I-backsheet ihlinzeka ngokufaka ugesi ukuvimbela amaseli ukuthi axhumane nendawo yangaphandle futhi abangele ukuvuza kukagesi noma ukujikeleza okufushane.

Ukusekelwa kwemishini: I-backsheet inikeza ukusekelwa kwesakhiwo sayo yonke iphaneli yelanga, igcina amandla onke kanye nokuzinza kwengxenye.

Ukuphathwa kwe-thermal: I-backsheet isiza ukuqeda ukushisa, ukunciphisa izinga lokushisa le-solar panel, futhi ithuthukise ukusebenza kahle nokusebenza kweseli.

Ilanga lasolwandleayigcini nje ngokuba nama-backsheets ekhwalithi ephezulu, kodwa futhi inweba ngokwehlukahlukana, ihlinzeka ngamabhodi amhlophe avamile, ama-backsheets amnyama wonke, nama-backsheets asobala.

·Ingilazi: Ukusebenza Nokuqina Kwamaphaneli elanga

Ukuvikelwa: Umsebenzi oyinhloko wengilazi yelanga ukuvikela amangqamuzana elanga ezintweni zemvelo ezifana nemvula, iqhwa, umoya kanye nemfucumfucu. Iqinisekisa ukuqina nokuphila kwephaneli yelanga.

Ukungafihli: Ingilazi yelanga iklanyelwe ukuthi ibe sobala kakhulu ukuze ivumele ukukhanya kwelanga kudlule kumaseli elanga. Lapho ukukhanya kufinyelela emangqamuzaneni amaningi, kulapho angaphehla khona ugesi.

I-Anti-reflective coating: Izinhlobo eziningi zengilazi yelanga ziza nezingubo zokulwa ne-reflective, ezinciphisa inani lokukhanya elibonakala phezulu, ngaleyo ndlela zandise inani lokukhanya elimuncwa amaseli elanga.

I-Tempered: Ingilazi esetshenziswa kumaphaneli elanga ivamise ukuthukuthela ukuze iqine futhi imelane nomthelela. Ingilazi epholile iphinde imelane kakhulu nengcindezi yokushisa, okubalulekile ngoba amaphaneli avezwa emazingeni okushisa ahlukene.

Izakhiwo zokuzihlanza: Ezinye izinketho ezithuthukisiwe zengilazi yelanga zihlanganisa ungqimba lwe-hydrophobic olusiza ukugcina indawo ihlanzekile ngokuxosha amanzi nokungcola, okunganciphisa ukusebenza kahle kwephaneli.

Ilanga lasolwandleikhetha ngokuqinile ingilazi efuthekayo enamandla amakhulu enokudlulisa ukukhanya okuphezulu ukuze kuqinisekiswe ukusebenza kwe-premium kanye nokuqinisekiswa kwekhwalithi ende yomkhiqizo ngamunye wephaneli yelanga.

·I-EVA: Ihlinzeka ngokunamathela kanye nokudluliswa kokukhanya kumaphaneli elanga

I-Encapsulation: I-EVA isetshenziswa njengempahla yokufaka ukuvikela amaseli e-photovoltaic. Ivamise ukubekwa phakathi kwengilazi namaseli elanga phezulu, naphakathi kwamaseli kanye ne-backsheet phansi.

Ukuvikelwa: I-EVA ivikela ekucindezelekeni kwemishini, izimo zemvelo (njengomswakama nemisebe ye-UV), kanye nokulimala okungaba khona ngokomzimba. Isiza ukugcina ubuqotho besakhiwo sephaneli yelanga.

Izakhiwo ze-Optical: I-EVA inokucaca okuhle, okwandisa ukudluliswa kokukhanya kumaseli elanga. Lokhu kubalulekile ukugcina ukusebenza kahle okuphezulu ekuguquleni ukukhanya kwelanga kube ugesi.

Ukunamathela: I-EVA isebenza njengongqimba olunamathelayo, oluhlanganisa izingxenye ezihlukene zephaneli yelanga ndawonye. Ngesikhathi se-lamination, i-EVA iyancibilika futhi ibophe ngokuqinile izendlalelo, iqinisekise ukuzinza nokuqina.

Ukuzinza kwe-Thermal: I-EVA iklanyelwe ukumelana nezinguquko zezinga lokushisa amaphaneli elanga angaphansi kwawo phakathi nempilo yawo yesevisi. Ihlala izinzile futhi isebenza phezu kwezinga lokushisa elibanzi.

·Uhlaka lwe-Aluminium: Inikeza ukuvikeleka nokufaka ukwesekwa kwamaphaneli elanga

Ukusekelwa kwesakhiwo: Ozimele be-Aluminium bahlinzeka ngobuqotho besakhiwo kumaphaneli elanga, okusiza ukubamba ngokuqinile izendlalelo (njengengilazi, i-EVA, amaseli elanga ne-backsheet) ndawonye.

Ukukhweza: Uhlaka lwenza kube lula ukukhweza amaphaneli elanga ezakhiweni ezihlukahlukene, ezifana nophahla noma amasistimu agibele phansi. Ivamise ukufaka izimbobo ezimbozwe ngaphambilini noma izikhala zokukhwezwa kwehadiwe.

Ukuvikela: Amafreyimu e-Aluminium asiza ukuvikela unqenqema lwamaphaneli elanga emonakalweni wokusebenza, njengomthelela noma ukugoba. Iphinde inikeze ukuqina okwengeziwe, ukunciphisa ingozi yokulimala ngesikhathi sokuphatha nokuthutha.

Ukuqina: I-Aluminiyamu ayisindi, iqinile futhi ayikwazi ukugqwala, iyenza ibe into efanelekile yokusetshenziswa kwangaphandle. Uhlaka lusiza ukuqinisekisa ukuthi amaphaneli elanga angakwazi ukumelana nezimo zemvelo ezinzima, okuhlanganisa umoya, imvula neqhwa.

Ukukhishwa kokushisa: I-Aluminium inokuhamba kahle kwe-thermal futhi ingasiza ekuqedeni ukushisa okuvela kumaphaneli elanga. Lokhu kusiza ukugcina ukusebenza kahle kwamaseli elanga, njengoba ukushisa ngokweqile kunganciphisa ukusebenza kwawo.

Ilanga lasolwandleisebenzisa ifreyimu ye-aluminium eqinisiwe engu-30mm/35mm, engagcini nje ngokukhanya futhi kulula ukuyifaka, kodwa futhi inikeza ukuvikelwa kwamandla aphezulu.

Isikhathi sokuthumela: May-30-2024